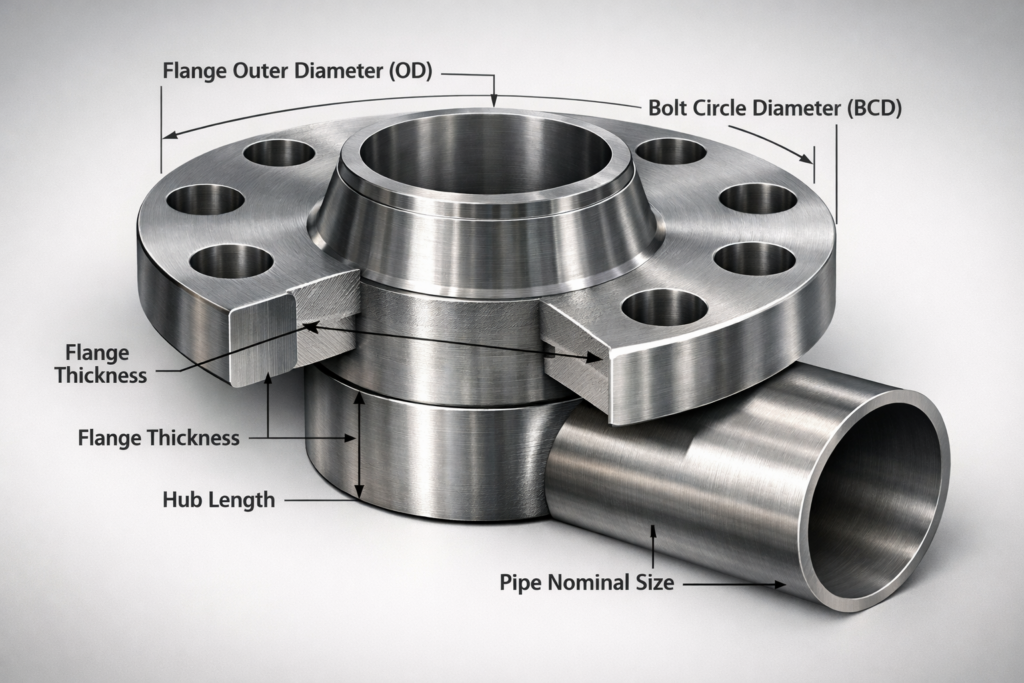

What are the critical dimensions of a weld neck flange? You need to match the flange’s Nominal Pipe Size (NPS) and Pressure Class to your system. However, a complete specification also includes the Outside Diameter (O.D.), Bolt Circle Diameter (B.C.D.), Hub Length, and precise Bore size to ensure a proper, leak-proof connection. These dimensions are standardized by ASME B16.5 (for NPS ½” to 24″) to ensure safety and interchangeability in high-pressure systems.

Why Weld Neck Flange Dimensions Are Critical

Weld neck flanges are designed for demanding applications where system failure is not an option, such as in oil and gas, chemical plants, and power generation. Their long, tapered hub is engineered to provide a smooth transition that distributes mechanical stress away from the weld joint and into the pipe, preventing failure points.

An incorrect dimension can break this design. A mismatched bore creates internal turbulence. An incorrect bolt circle means the flange won’t mate with its pair. This is why precise adherence to published dimensional standards is a fundamental requirement, not just a suggestion.

Key Dimensions and How to Read Them

Every weld neck flange is defined by a set of standard measurements. Here are the most important ones, based on the ASME B16.5 specification:

| Dimension (Symbol) | What It Is | Why It Matters |

| Nominal Pipe Size (NPS) | The nominal size of the pipe it connects to (e.g., 2″, 8″, 24″). | This is your starting point. It roughly correlates to the pipe’s inner diameter. |

| Pressure Class (Rating) | The pressure-temperature rating (150, 300, 600, 900, 1500, 2500). | Determines the flange’s thickness and strength. A Class 300 flange is thicker and has more bolts than a Class 150 of the same NPS. |

| Outside Diameter (O.D.) | The overall width of the flange face. | Must be correct to fit within the allotted space and allow for bolt tightening. |

| Bolt Circle Diameter (B.C.D.) | The diameter of the circle through the centers of all bolt holes. | Critical. This must match exactly on mating flanges for bolts to align. |

| Bore (B) | The inner diameter of the flange’s hub and weld neck. | Must match the outer diameter of the specific pipe schedule (wall thickness) for a proper butt-weld fit-up. |

| Thickness (T) | The thickness of the flange’s body. | Increases with pressure class to handle greater internal forces. |

| Length Through Hub (Y) | The length of the tapered hub from the base to the weld point. | A key identifier of a weld neck flange. Provides the stress-reducing transition. |

| Number & Diameter of Bolt Holes | The count and size of holes for the stud bolts. | Increases with size and pressure class to ensure a tight, even seal. |

How Dimensions Change with Size and Pressure

The physical size of a flange increases with both its Nominal Pipe Size (NPS) and its Pressure Class. For example, a 6-inch flange is physically larger than a 2-inch flange. More importantly, a Class 600 flange is significantly heavier and has a larger bolt circle than a Class 150 flange of the same NPS.

The table below illustrates this by comparing key dimensions for a 6-inch (NPS 6) weld neck flange across three common pressure classes. All data is per ASME B16.5 standards.

| Dimension | Class 150 | Class 300 | Class 600 |

| Outside Diameter (O.D.) | 11.00 in | 12.50 in | 14.00 in |

| Thickness (T) | 0.94 in | 1.12 in | 1.31 in |

| Bolt Circle Diameter (B.C.D.) | 9.50 in | 11.00 in | 12.50 in |

| Number of Bolt Holes | 8 | 12 | 12 |

| Bolt Hole Diameter | 0.88 in | 1.00 in | 1.12 in |

The Importance of the Bore and Special Types

For a proper, full-penetration butt weld, the bore of the weld neck must be machined to match the outer diameter and bevel of the specific pipe being used. This match ensures smooth flow, minimizes turbulence, and creates a strong, inspectable weld.

Two specialized variants depend heavily on precise dimensions:

- Ring-Type Joint (RTJ) Facing: For ultra-high-pressure services, weld necks often have an RTJ face with grooves for a metal ring gasket. The dimensions of these grooves are as critical as the flange’s body dimensions.

- Long Weld Neck (LWN) Flanges: Also called nozzle flanges, these have an extended hub and are used for vessel connections. Their overall length and internal bore are custom-managed based on the engineering requirements of the tank or pressure vessel.

Inspection and Common Challenges

When inspecting or ordering a weld neck flange, you should verify all major dimensions: outer and inner diameters, bolt circle, hub length, and bore. The most common specification errors involve:

- Mixing Pressure Classes: Assuming a Class 150 and Class 300 of the same NPS are interchangeable (they are not).

- Ignoring the Bore: Ordering a “standard bore” without confirming it matches your pipe’s actual wall thickness (schedule).

- Overlooking the Facing: Not specifying if a Raised Face (RF), Flat Face (FF), or Ring-Type Joint (RTJ) is required.

Getting these details right requires precision and access to the correct specifications or a supplier that can guide you.

Need weld neck flanges machined to exact specifications? We can provide standard ASME B16.5 flanges or custom-machined pieces, including long weld necks and RTJ facings, in carbon, stainless, and alloy materials. Submit your detailed requirements for a precise quote: http://texasflange.com/lp12/

Frequently Asked Questions

Q: Can I get a weld neck flange with a bore larger than standard?

A: Yes. Flanges can be custom-bored (“bored to match”) to fit the exact outer diameter of any pipe schedule. This is essential for a proper butt-weld connection.

Q: What’s the difference between a standard weld neck and a long weld neck (LWN) flange?

A: An LWN has a significantly longer, often straight, hub. It’s designed to be a nozzle on a pressure vessel or tank, replacing a standard flange-and-pipe weld combination. The length is a custom dimension based on the application.

Q: Where do I find the complete dimensional table for all sizes and classes?

A: The governing standard is ASME B16.5. Reputable flange suppliers like Texas Flange also publish detailed dimension charts for each pressure class on their website for reference.

Q: Are dimensions for a 150-pound flange the same across all manufacturers?

A: For flanges marked ASME B16.5, the critical dimensions (O.D., B.C.D., bolt holes, thickness) must be identical to ensure compatibility. However, minor proprietary variations in hub contour or non-critical weights may occur.